SmithKline & French. 1978

SK&F CO

SK&F LAB CO

Two Companies

SMITHKLINE BECKMAN

Description

Date of Completion: April, 1983

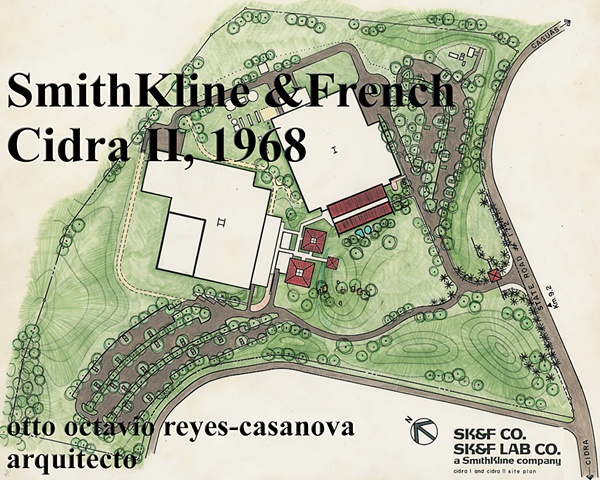

Location: State Road # 172, Km. 9.2, Cidra, Puerto Rico

Use of Structure: Pharmaceutical

Program Description:

Construction of a 200,000 square feet plant (Cidra II) for the manufacturing of Tagamet, on a site where a first plant (Cidra I) was already built since 1976, also designed by us.

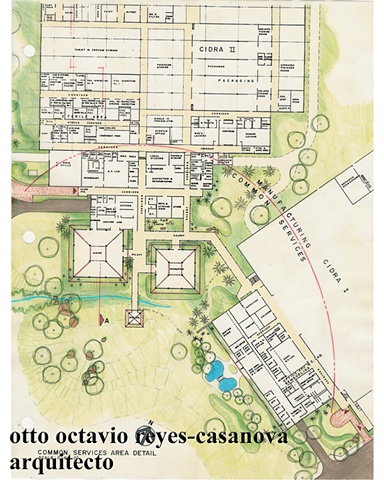

Integration of all possible common services to both plants.

Exert utmost care with an ecological fragile site, adjacent to the Cidra lake, and blessed with exceptional natural beauty.

Material & Construction Type:

Structural Steel, Concrete, Block walls and Wooden Roofs.

Cost: $ 22 millions

SK&F CO

SK&F LAB CO

Two Companies

SMITHKLINE BECKMAN

CONCEPTS

The program required the construction of a second plant (Cidra II) in the same site and adjacent to the original plant (Cidra I) built in 1976. This first project was quite successful in its integration to the site and surroundings and the Owner wanted to repeat the formula. It was not easy to convince the Client that Cidra I was too strong a statement, unique, and not repeatable.

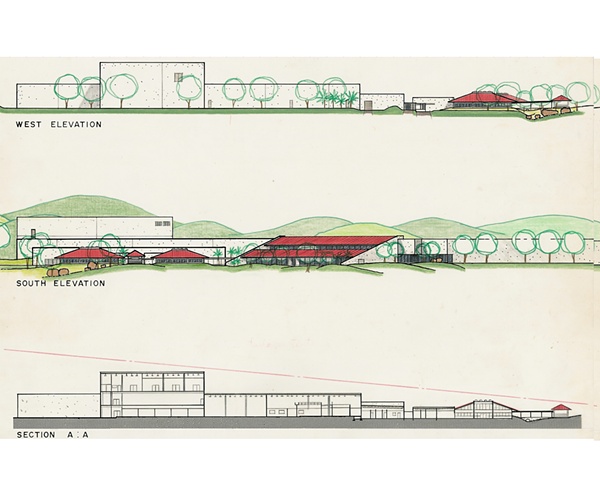

Hence, the concepts developed relates both projects by contrast, complementing the single, hard, long tile roof of Cidra I, with independent, fractured pavilions and volumes of Cidra II, partially hidden behind an existing hill seeded with magnificent rock outcrops. This is a spatial relation of positive-negative forms, a sort of a harsh-soft dependence on each other. The Cidra II building is a much bigger footprint and a taller building with a three level volume (tablet manufacturing 52’/16m). This unwanted visual impact on the site is diluted by receding the forms in width and height toward the back, maintaining its balance during the access sequence thru the site.

Other concepts developed are:

A. Integration of common facilities for both plants, administration, dining,

recreation, quality control, laboratories, dispensary, mechanical and electrical

services. This was achieved by converting all of the Cidra I tiled wing solely into

offices and building the new dining and recreation pavilions and the low masses

for the common services which in turn help in the volume transition.

B. Simplifying a complex interior flow by logical, clear cut, circulation patterns which in turn define Cidra II. Three mayor areas, color coded in the interior and separated by in-process storage, are: 1. the 3 level, vertical flow, tablet production area; 2. sterile area; 3. packing area.

C. Use of the excess cut of 150,000 cm in the earthwork to form two large mounds

which block a neighboring plant built after Cidra I, which unfortunately affected

the axial view of the Cidra Plateau. These mounds integrated to the rolling character of the farmland, contain the space and control the views.